crafted tools. I just wanted to share a few tools I've made (at a very modest cost) to work on my cars.

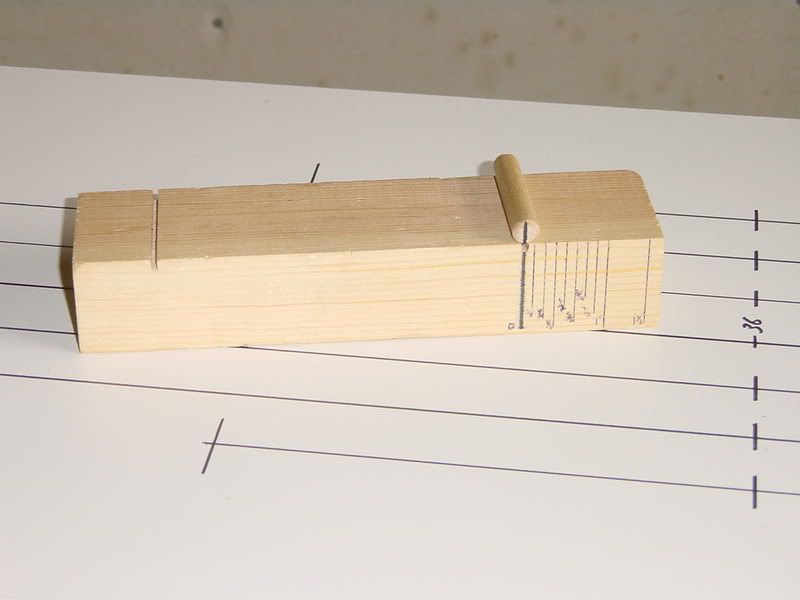

My ultra cheap car ballance point finder thingie. One pinewood block, a short length of dowel glued into an axle groove,

and a few lines with a sharpie.

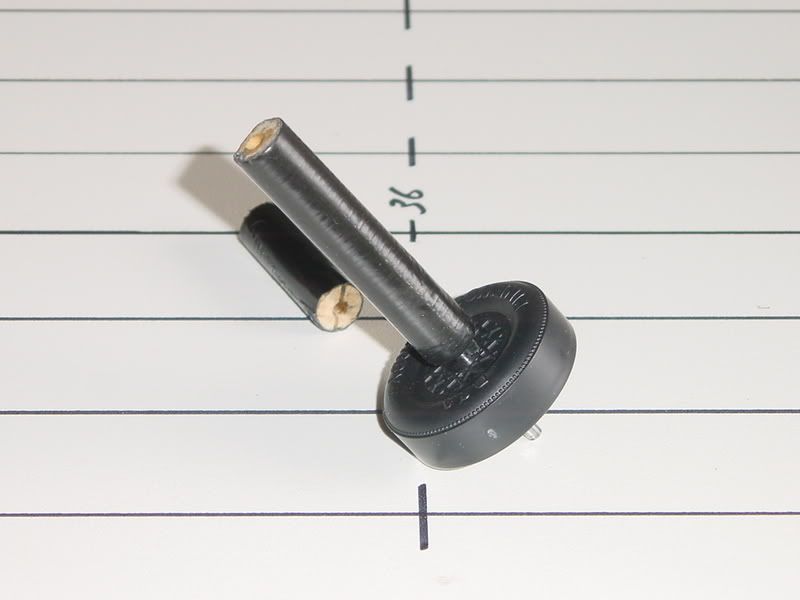

This thing was also VERY cheap to make. It's for squaring up the hubs, both inner and outer. Another short length of

dowel with a small hole drilled in the end (took several trys to get that right). Then make a small cut in the end of the

dowel for the razor blade to insert into. Insert a .097 guage pin (or polished drill bit) in the hole, and superglue in a

small bit of razor blade you broke off with a pair of plyers into the groove at a right angle to the pin.

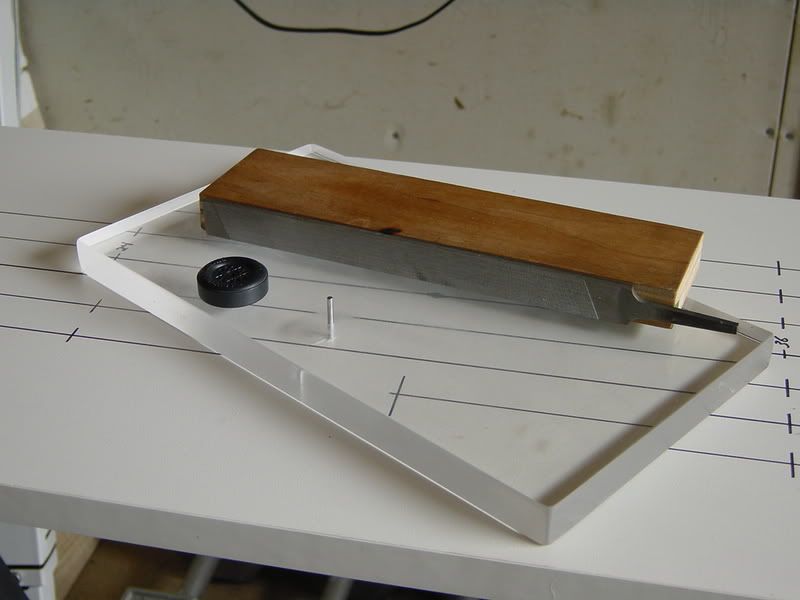

And finally, my wheel jig. I started out using a flat chunk of quality plywood I scrounged from a cabinet shop. Drill a

hole in aproximately the center with a drill press or hand drill. Then use a square to epoxy in a guage pin (size to suit yourself)

so that it sticks roughly 1 inch above the deck. Now all you need is a second plywood block, about 2 1/2 inch wide x 7 inch

long. Place a file or strip of sandpaper against the smaller block's edge, and gently push it against the wheel you inserted on

the pin. Now, carefull not to let the block move, turn the wheel by hand. The file will catch the high spots, and with some practice

you will get very good at making quality wheels.

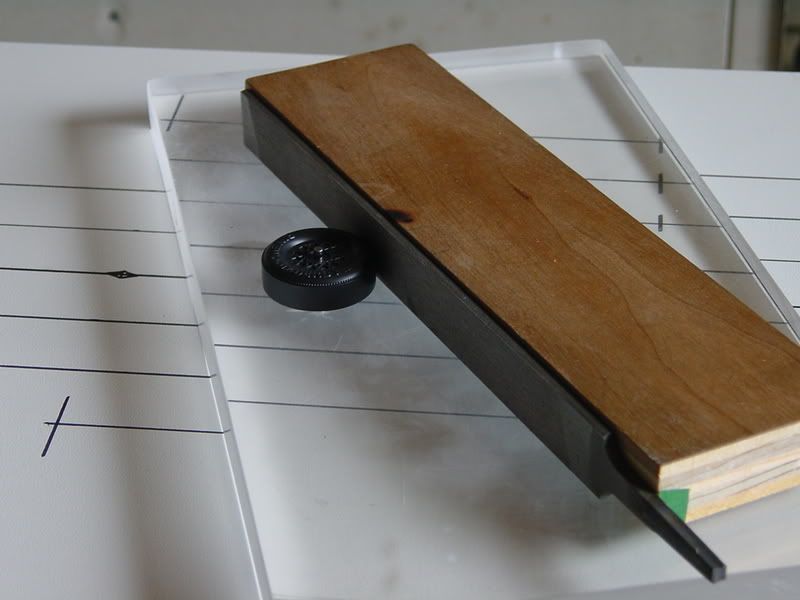

My current variation of the wheel jig uses a 3/4" chunck of plexiglass. I found that was more stable, and allowed me to use

liquid lubricants (vasoline or krytox) on the pin while turning wheels. I also was able to dish out the deck where the pin inserts

into the plexiglass by wrapping a strip of sandpaper around a shooter marble and turning it over my drill hole. That allowed

me to place a strip of sandpaper over the pin, then the wheel with inner hub down. A few turns with downward pressure and

you've got a coned hub.

All 3 tools, less than $25, and that's only because I blew $10 on the plexiglass getting it cut to size.